When I began to make silkscreens for polymer clay about 10 years ago I never dreamed they would become so popular. The late Gwen Gibson, a Pioneer in the World of Polymer Clay, innovated the use of silkscreens and etching plates with Polymer Clay. Gwen was generous and I was fortunate to chat with her on a couple of occasions. Although I also use acrylic paint, which is the medium Gwen had primarily used with silkscreens, my passion has always been Mica. I then added Chalk and Pan Pastel. I began using Metal Pulvers in 1989 and then moved to the less toxic Mica. Back in 1989 no one told you about wearing a mask when using the pulvers or fine metal shavings and when Jacquard introduced Mica powder for Card making, scrap-booking etc (which we also use in make-up and eyeshadow) this wasn’t necessary. If you use a brush and really go at it, you might want to wear a mask, though. I primarily use my fingers to apply.

For many years I sold this tutorial, but have decided to share some of my older tutorials as I develop newer ones. Enjoy!

“Low Relief Stone Rubbings”

by Tina Holden (2008)

This is an older tutorial, but still valid. I just reformatted the layout of the text. Here I will teach you how to create 'low relief stone rubbings' on Polymer Clay. These stone rubbings are based on grave stone rubbings, but aren't as morbid. Instead you'll discover various ways and possibilities with this technique using silkscreens or stencils.

Tools:

● Tissue blades, rigid and flex (flex is optional)

● Pasta Machine (Atlas 150 used in examples)

● Needle tool or knitting needle

● Silkscreens or stencils

● round, oval or square cutters (optional)

● Flat soft bristle paintbrush

● Oven

● Baking tile or glass

● White unlined paper or card stock to bake on

● Thin Foam texture sheet or other suitable texture such as silken fabric or tulle

● Armorall as release agent

● Baby wipes or Windex for clean-up

● gloves (optional)

Materials:

● Premo! Polymer Clay: 1 small block each of white, translucent or frost, pearl and either Turquoise

Blue or Sea green (note: Sea Green is no longer available)

● Fimo Gloss or Fimo Water based Varnish

● Decorator Chalks (or pastel powder eye make-up in cobalt blue, bright green and yellow) or Pan Pastels in similar colours

● Jacquard PearlEx Mica Powder in Turquoise (optional)

● Embossing powder in green, blue or verdigris

The clay I prefer is Premo but you can use any of the other brands if you prefer, although for jewelry I don't recommend Sculpey III as it is too brittle for thinner pieces. (note…this is the older Premo packaging)

Preparing the Clay base:

Step 1. Mix ½ block each of white, translucent, and pearl with ¼ block of turquoise or sea-green. Roll through Pasta machine on thickest setting (#1 on Atlas)

.

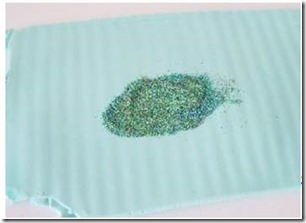

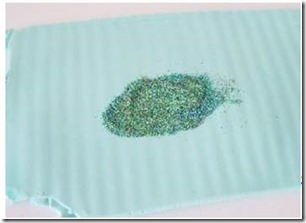

Step 2. Blend clay with 1 tsp. of embossing powder.

Step 3.Blend clay with ¼ tsp. of Turquoise Mica Powder (optional). Roll through pasta machine on thickest setting (#1 on Atlas).

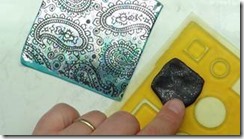

Step 4. Cut sheet in half and lay one half aside. Prepare Silkscreen by using a little Armorall on finger and spread over the 'rubbery' side of the screen. This will prevent the fine mesh from clogging up with clay. Roll out on smaller setting, next size down, #2 on Atlas.

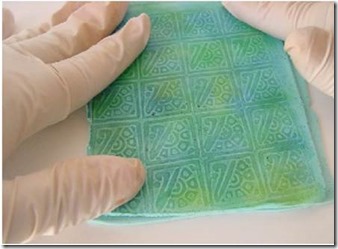

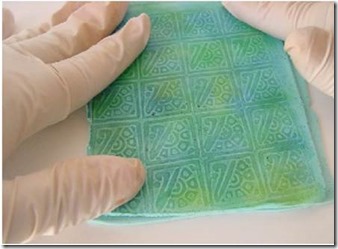

Step 5. Stack Silkscreen – shiny side down onto prepared clay sheet, with foam texture or tulle at backside of clay. Roll through pasta machine on thickest setting (#1 on Atlas).

Step 6. Peel off Silkscreen and texture. You should get a low relief or stamp-like texture on your clay. (I’ve darkened the first photo so you might be able to see the texture a little better)

Colouring the relief texture:

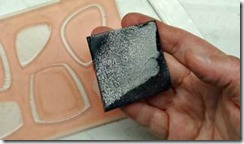

Step 7. Lightly cover finger or gloved finger with chalk and gently stroke or rub

Colour onto your textured sheet. Don't apply too much pressure as you will want to keep your texture intact. Start with one colour and apply in various places on the relief. I used green chalk here.

Step 8. Then apply another colour/s. Second colour I used is blue, third I used yellow. Cover entire sheet until you are pleased with the effect. You may have to go over the surface with more powder to darken it. It doesn't really matter if you apply some green over the blue, it'll actually turn it into a nice teal.

Step 9: Take sheet that you laid aside earlier and roll out at #2 setting and then texture one side with foam texture or tulle. Remove foam or tulle and carefully lay your coloured relief rubbing sheet onto the sheet you textured (texture side down), avoiding trapping air bubbles.

Step 10: Trim away rough edges. Any of the coloured scraps put aside to roll into matching beads later if you want to.

Step 11: Cut into tiles for Bracelet, Earrings, put holes where you need them. Other creative uses would be for coasters or tiles.

Step 12: When putting in holes horizontally, Hold the tile as shown and maneuver a thin needle or needle tool through the tile, just until it peeks through the other side. Complete the hole by pushing tool through from opposite end. For a bracelet you'll need about 5 to 7 tiles, it depends on what size beads you use as spacers, on wrist size as well as the tile size. I do have a tile bead tutorial on both my website and Etsy (links below)

Step 13: Rub some chalk or pastel on the sides and back of the bead tiles also.

Step 14: Bake, Let cool and varnish, then string with elastic. Tie knots and hide knots inside large-hole glass beads.

Note: you can roll your unbaked/uncured stone rubbing through smaller settings to lightly stretch the design which I did with the earrings here.

For variation try other colour combos and other patterns.

Variation: mix a different colour clay base such as ½ ecru, ¼ translucent, ¼ pearl, ¼ raw sienna and use chalks in brown and orange. Always use a light colour clay base to bring out the colours of the chalk.

Have Fun creating!!

Tina

For a variety of silkscreens, molds, tutorials etc…

My Etsy:

https://beadcomber.etsy.com